Ceramic Filtration is a legendary method adopted to make water potable. Over the years, this technology has become more and more sophisticated to increase effectiveness. The ceramic cartridge is porous, which allows water to pass through it. The size of these pores is the determining factor for the effectiveness of the cartridge. It is like a sieve- we would chose a fine sieve to remove bigger unwanted particles. The ceramic cartridge would be a similar structure with millions of layers of the sieve put together.

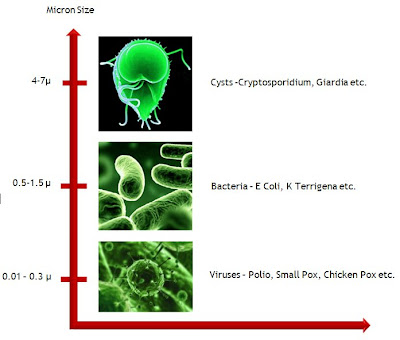

The pore size of the ceramic cartridge is measured in microns which is one millionth of a metre. It is not visible to the naked eye. The main purpose of using a sophisticated ceramic cartridge is to remove micro-organisms and also achieve particulate filtration. Particulate filtration would include removal of dust, sand, etc that is usually very fine and may also be visible in the water. The microorganisms are a major concern- causing illness which may even be fatal in the case of children and the elderly.

The main cause of apprehension would be bacteria, cysts and viruses when it comes to microorganisms. The sizes of these microorganisms are also measured in microns. The pore size of the ceramic does not directly relate to the removal properties with respect to the size of the microorganism. In the case of a sieve, there would be typically only one layer to filter the required particles. But in the case of the ceramic cartridge, there are millions of layers that the microorganism needs to pass through before it could leave the filter.

Using a sophisticated ceramic filter, cysts and bacteria are effectively removed. It is not possible to remove viruses using ceramic water filters due to their infinitesimal micron size. A premium ceramic cartridge would have colloidal Silver impregnated in it. As Silver is known for its sterilizing properties, this would inhibit the growth of microorganisms in the ceramic structure.

Ceramic Cartridge

The ceramic cartridge is a hollow cylindrical structure with one closed end and one open end. Water seeps through the cartridge and flows out of the open end. The ceramic wall is usually of about 1- 3 cms in width. The hollow portion of the ceramic cartridge has added benefits. This portion can be filled with an activated Carbon block, Granular Activated Carbon, Ion Exchange resin or both activated Carbon and Ion Exchange resin. Activated Carbon is used to remove chlorine, VOCs and unpleasant odour via a process called Adsorption. The respective Ion Exchange resin is utilized to remove heavy metals that might be present in the drinking water. Both Activated Carbon and the resin will perform effectively only during its life period, after which they need to be replaced.

The biggest advantage of using a ceramic candle is the fact that the outer ceramic can be cleaned periodically using a scouring brush which would remove the slush and dirt filtered. When doing so, a very small layer of the ceramic is removed exposing a brand new layer for re-filtering. Depending on water conditions, the ceramic cartridge should be cleaned to increase the flow rate of the water filtration. In the cases where the ceramic cartridge is filled with Activated Carbon or Ion- Exchange resin, the life of the cartridge would be limited with respect to the expiration of the added Carbon or resin.

The ceramic technology can be incorporated in different types of water filters. The water filter most commonly used with ceramic filters would be the ceramic gravity fed water filters. There are usually two chambers – one for the water to be filtered and one for the filtered water. The top chamber is filled with the water to be filtered and there are 1- 6 ceramic cartridges used in the filter. When gravity takes its action, the water is forced through the ceramic cartridges and dribbles out into the enclosed lower chamber. The lower chamber is fitted with a leak proof tap and stores the freshly filtered pure drinking water.

The usage of the ceramic cartridge has expanded in recent times. They are now incorporated with Countertop water filters and Under-sink water filters. They are ‘direct on line’ or ‘point of use’ systems where filtered drinking water is available on demand. The Countertop water filter requires no plumbing and can be attached to the spout of the kitchen sink using a diverter valve. With a flick of a switch, the customer would be able to choose between filtered water and unfiltered water.

The Under-sink water filter is a permanent solution for filtered drinking water. The Under-sink water filter is also called a pressure filter as it is under pressure at all times as it is connected to the cold mains water supply. They are designed to be plumbed in under the sink and come with a spout that is fitted on the counter. It is a sleeker and stylish alternative for a long term solution and clutter free bench top.

It is important to use a chemical free and long lasting housing for the Under-sink water filter such as Stainless Steel. This would give the housing an infinite life time and eliminate worries about chemicals leaking into the filtered water. Plastic housings usually encounter breakage when changing filters and also need to be replaced after 5 – 10 years. A good investment would be in a long lasting and trust worthy housing.